Have you ever sprayed your favorite perfume and wondered how this magical liquid was created? Perfume-making is both an art and science, combining natural essences, chemistry, and craftsmanship.

In Pakistan, where fragrances are deeply rooted in culture (from traditional attars to modern designer scents), understanding perfume production makes you appreciate each bottle even more. Let’s explore:

✔ The raw ingredients used in perfumes

✔ Traditional vs. modern production methods

✔ How Pakistani brands craft unique scents

✔ From lab to bottle – the final steps

1. The Raw Ingredients of Perfume

A. Natural Ingredients

- Flowers: Rose, jasmine (used in Pakistani gulab attars)

- Woods & Resins: Oud, sandalwood (popular in Islamic fragrances)

- Citrus Fruits: Bergamot, lemon (for fresh top notes)

- Spices: Saffron, cardamom (adds warmth)

B. Synthetic Ingredients

- Musk: Lab-created for consistency

- Alcohol: Preserves and carries fragrance

- Fixatives: Makes scents last longer

💡 Did You Know? It takes 10,000 roses to make 1kg of rose oil!

2. Traditional vs. Modern Perfume-Making

A. Traditional Methods (Attars)

- Steam Distillation: Flowers/woods boiled to extract oil

- Used in: Pakistani kannauj attars, mukhallats

- Pros: Alcohol-free, long-lasting

- Cons: Time-intensive (weeks to produce)

B. Modern Methods

- Chemical Extraction: Faster, more consistent

- Used in: Designer brands (e.g., J., Junaid Jamshed)

- Pros: Affordable, diverse scents

- Cons: Some use synthetic alcohol

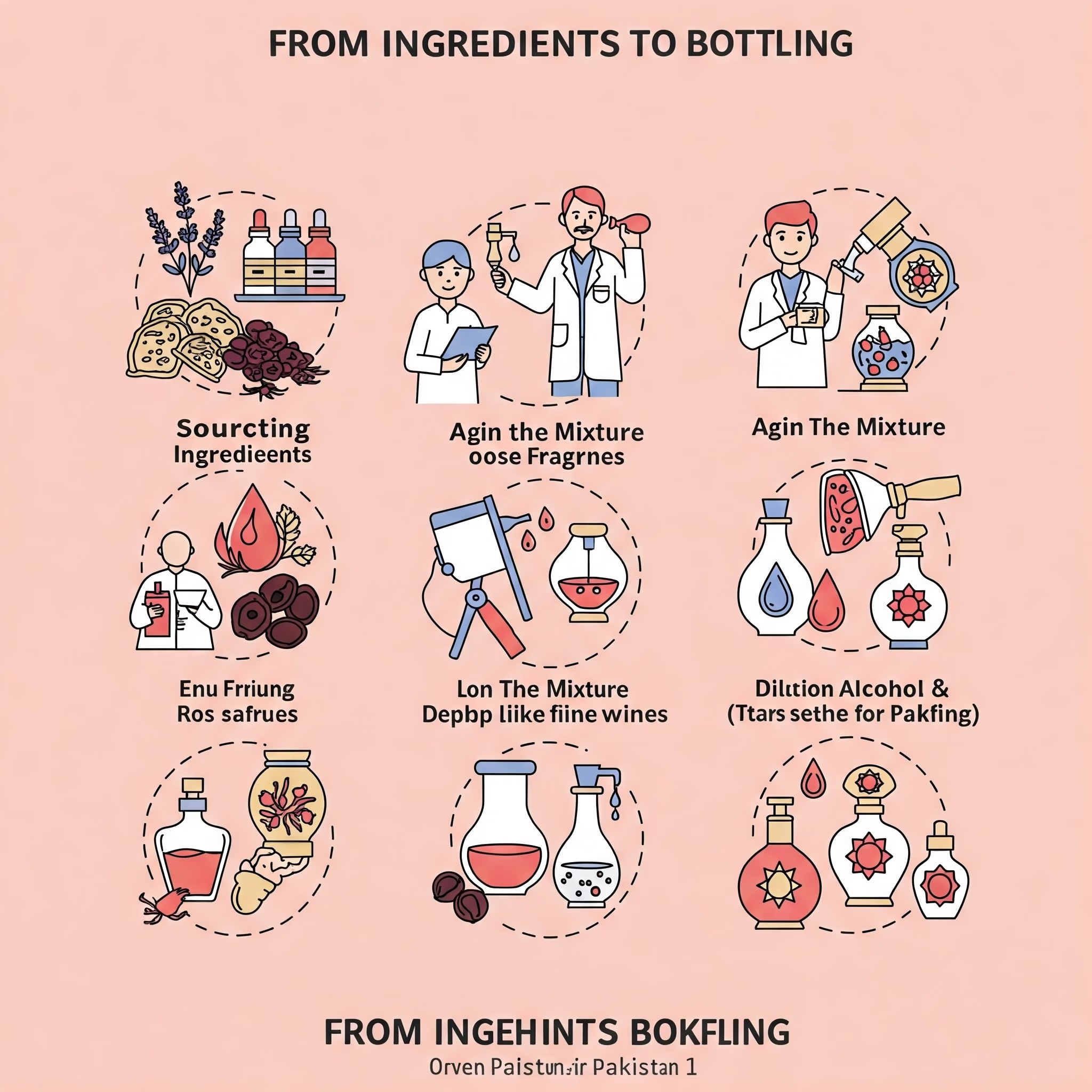

3. The 5-Step Perfume-Making Process

Step 1: Sourcing Ingredients

- Pakistani brands import some essences (like French lavender) but use local rose, oud, and saffron.

Step 2: Blending Oils

- A perfumer (nose) mixes top, middle, and base notes to create a balanced scent.

Step 3: Aging the Mixture

- Perfumes rest for weeks to months to develop depth (like fine wine!).

Step 4: Adding Alcohol & Fixatives

- Diluted with alcohol (or oil for attars) and fixatives for longevity.

Step 5: Bottling & Packaging

- Filled into decorative bottles, often hand-finished in Pakistan.

4. How Pakistani Brands Craft Unique Scents

Local brands like Fusion Scents blend:

✔ Traditional oud and rose (cultural heritage)

✔ Modern fruity/floral notes (global trends)

✔ Halal-certified ingredients (for religious compliance)

🌟 Example: Our bestselling “Saffron Rose” combines Pakistani rose oil with Spanish saffron.

5. Testing & Quality Control

Before bottling, perfumes undergo:

- Skin tests (for irritation)

- Longevity checks (how long it lasts in heat)

- Scent consistency (every batch must match)

6. From Factory to Your Hands

- Hand-Filling: Some luxury brands fill bottles manually.

- Automated Lines: Mass-market perfumes use machines.

- Packaging: Boxes often feature Urdu/Pakistani designs.

7. DIY: Can You Make Perfume at Home?

Yes! Try this simple recipe:

- Mix 2 tbsp vodka (or almond oil) + 10 drops rose oil + 5 drops vanilla.

- Age for 48 hours in a dark place.

- Pour into a spray bottle.

(For stronger scents, use oud or sandalwood oil.)

Where to Experience Perfume-Making in Pakistan?

Want to see the process live? Some brands offer:

✔ Factory tours (e.g., in Karachi, Lahore)

✔ Workshops (blend your own scent!)

Final Thought: Perfume-Making is Magic!

Next time you spray your favorite fragrance, remember—it’s a masterpiece of nature, chemistry, and culture.

🛒 Explore Pakistani-Made Perfumes Shop Now